H

E

R

K

K

I

M

E

R

- MIDC Bhosari, Pune, Maharashtra, India

- Time : Mon-Fri : 9:30AM – 6:00PM | Sat : 9:30AM – 2:00PM.

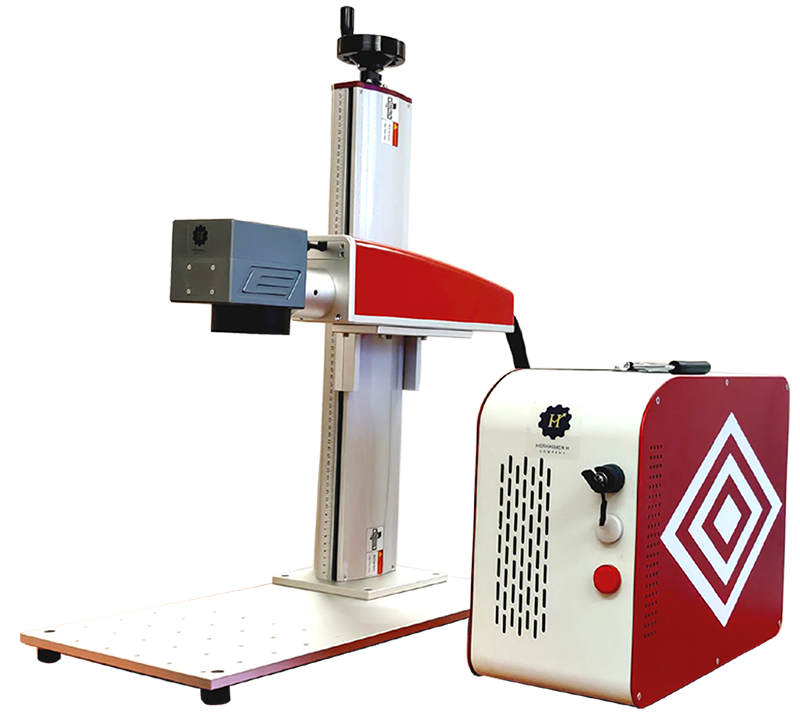

- Marking Solutions

- World-Class Quality